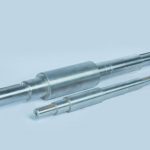

Pattern & Dies

We have in-house Design Team using AutoCAD, SolidWorks and EdgeCAM software to design all our casting tooling – patterns and dies. We also manufacture them. The castings are produced in various reputed foundries who are selected and approved by us.

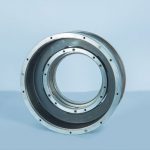

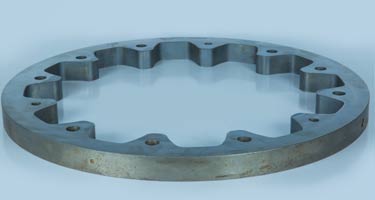

Iron Castings

Grey Iron Castings

• ASTM A48 – Class

• EN – GG15, GG20, GG25, GG30, GG35

• Indian – FG150, FG200, FG260, FG300, FG350.

Ductile Iron Castings

• ASTM A536 – 400/15, 500/7, 600/3, 700/2

• DIN – GGG40, GGG40.3, GGG50, GGG60 and GGG70

Weight – Single piece from 1kg to 5000 kg.

Moulding Process – Green Sand Moulding, Resin Sand Moulding and Shell Moulding

Carbon Steel Castings

Carbon Steel Castings:

• ASTM 216 Gr. WCB, WCC

Carbon Steel Castings for Low Temperature Service:

• ASTM A 352 Gr. LCB, LCC

Stainless Steel Castings

• ASTM A351 - CF3, CF3A, CF8, CF8A, CF3M, CF3MA, CF8M, CF3MN, CF8C, CF10, CF10M, CH8, CH10

• ASTM A743 - CF8, CG12, CF20, CF8M, CF8C, CH10, CH20, CE30, CA15, CA15M, CA40, CA40F, CF3, CF3M, CF3MN, CG3M, CG8M, CN7M, CA6NM, CK3MCuN

• 17-4 PH

Heat Resistant Castings

• ASTM A 351 - CH20, CK20, CD4MCu, HK30, HK40

• ASTM A 297 - HH, HK, HE, IS4522, SS310, SS309

Duplex Stainless Steel Castings

• ASTM A890, A995 - CD4MCuN, CD3MN, CD3MWCuN

Nickel Alloy Castings

Hastelloy:

• ASTM A494 - CY40, CW12MW, CX2MW, Hastelloy B, Hastelloy C, Hastelloy X, Udimet 500, Thetaloy, GMR-235, Alloy 20

Inconel:

• Inconel 625, 825, 713C, HS21, HS31, HA36 Castings

Monel:

• ASTM A494 - M35-1, M35-2, M25S

Weight – Single piece from 1kg to 10000 kg.

Moulding Process – No Bake Mould or Co2 Mould, Resin Sand Moulding and Shell Moulding

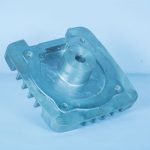

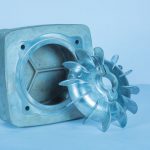

Aluminium Castings

ASTM B26 and ASTM B108 – 319, 355, 356 T6

Weight – Single piece from 100 grams to 150 kg.

Moulding Process – Permanent Mould / Gravity Die Casting and Sand Casting.

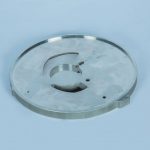

Copper Alloys

Brass (85-5-5-5), Tin Bronze (CuSn10), Aluminium Bronze and Lead Bronze.

Weight – Single piece from 100 grams to 50 kg.

Moulding Process – Shell Moulding and Sand Casting.

Central Lab

A well-equipped Lab to check the inward castings for Chemical, Mechanical, Micro and NDT.

• Bruker, Germany, Spectrometer

• Meiji, Japan, Microscope with Image Analysis

• Proceq, Sweden, non-destructive hardness tester

• NDT: MPI – Magnetic Particle Inspection and UT – Ultrasonic Testing